The working principle of the rolling shutter door

2023-01-20 11:58

Principle of operation

The rolling shutter door is mainly composed of door body, driver and control system. The door body is made of high quality stainless steel and aluminum alloy special profile, using the principle of parallelogram hinge, flexible expansion and large stroke. The drive is driven by special motor, the worm wheel is decelerated, and has manual clutch, which can be opened and closed manually during power failure. The control system has control board, button switch, and wireless remote control device according to user needs. Can be equipped with a scrolling display screen. It can also be equipped with intelligent infrared dual probe collision prevention device, when people or foreign matter 20-30cm can automatically return to operation, so as to ensure the safety of vehicles and pedestrians.

Function and characteristics

The rolling shutter door body is made of high quality stainless steel and other materials, using the principle of parallelogram handover, flexible expansion. The drive is driven by special motor, the worm wheel is reduced, and has manual clutch, which can be manually opened and closed when the power failure. The rolling shutter door is telescopic shed lattice type, which has the characteristics of smooth opening and closing, perspective door body and small space after opening.

1. By setting up an intelligent infrared anti-climbing device, the system will immediately alarm when someone climbs the door, so as to ensure the safety of the door.

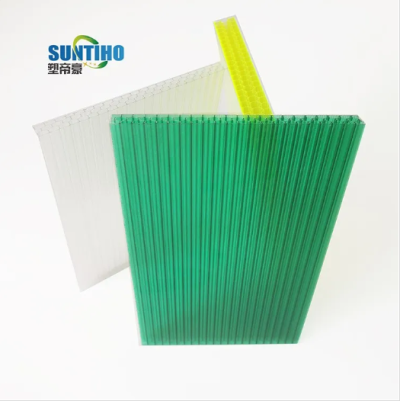

2. Special profile: in the high hardness zinc aluminum alloy profile with different geometric shapes and bones can greatly enhance its strength, the surface by special electrophoresis treatment, infinite luster, not easy to stick dust, not corroded by polluted gas, never rust, protect the new period is long.

3. Engineering plastics: the main plastic parts of the door body (such as the connection between pipe and pipe, plastic parts, door body moving parts, etc.) use high quality engineering plastics (such as PC, PA), high toughness, impact resistance, distortion resistance, wear resistance, wear resistance, frost resistance, sun resistance, not aging, long service life, from snow, thunder, lightning, sun and rain.

4, intelligent infrared probe anti-collision device: the door body can automatically return 30-50cm to operation, so as to ensure the safety of vehicles and pedestrians. Standard structure: the interior of the door row (i. e., the distance between the main pipe and the two bends, excluding the main size) adopts the standard size of the rolling shutter door 320mm (refer to foreign technology) to ensure the strongest cross pipe and greatly reduce the operating noise.

5. Unique process The main frame profile of the door body is made of plastic parts, and the screw design of the connection position is hidden to improve the appearance of the door body, and the connection between the profile and plastic parts is made of punching, pressing, drilling and other processes, so that the door body structure is firm and no solder joints. Cross connection design: the cross pipe is made of special process, and equipped with super PA wear-resistant sleeve. The close combination with the round tube not only makes the door row structure more firm, but also ensures the operation more smooth.

6. The beautification of the environment, improve the enterprise appearance and enhance the enterprise image; help to create civilized enterprise, civilized factory, civilized city atmosphere; and improve safety, even damage or over at night. Curshutter door is mainly used in living communities, government schools, enterprises and institutions, etc.

Inspection and maintenance

Check and maintain the access port; check and maintain the main shaft and auxiliary shaft; check and maintain the door body.

Inspection method and requirements

1. The inspectors shall be composed of professionals, and the inspection work shall be inspected by experienced professionals and technicians familiar with the subway situation.

2. The inspection can be conducted through visual, ear, hand touch, supplemented by corresponding tools and instruments.

3. General rolling shutter door, fire rolling shutter door, industrial lifting door, electric expansion door, pull gate and electric induction door must be operated, checked and adjusted normally after each sub-item inspection.

4. After the on-site inspection, the personnel and tools should be cleared, and the corresponding inspection implementation records should be made.

5. The on-site inspection and maintenance records must be sorted out in time and registered in the daily inspection and maintenance account.

Maintenance methods and requirements

1. The maintenance personnel should be composed of professionals, and the maintenance work must be checked by experienced professionals familiar with the subway situation. Maintenance personnel should not be arbitrarily changed.

2. General rolling shutter door, fire rolling shutter door, industrial lifting door, electric expansion door, pull gate, electric induction door must be carried out the overall operation, inspection and debugging after each maintenance operation.

3. After the on-site maintenance, personnel and tools shall be cleared, and corresponding maintenance records shall be made.

4. On-site maintenance records must be sorted out in time and registered in the daily inspection and maintenance account.

Get the latest price? We'll respond as soon as possible(within 12 hours)